Non-stick Pan Has Scratches and Peeling? Good Riddance!

A scratched and peeling non-stick pan can be a culinary nightmare. Fortunately‚ there are solutions to restore your cookware to its former glory‚ ensuring a safe and efficient cooking experience.

Introduction

A non-stick pan is an essential tool in every kitchen‚ providing a convenient and healthy way to cook a variety of dishes. However‚ over time‚ even the most well-maintained non-stick pans can develop scratches and peeling‚ compromising their performance and safety. This can be frustrating‚ especially if you have invested in a high-quality pan. Fortunately‚ there are ways to address these issues and extend the lifespan of your cookware.

In this article‚ we will delve into the world of non-stick pans‚ exploring the causes of scratches and peeling‚ and discussing the consequences of a damaged non-stick coating. We will also provide guidance on how to restore and fix a scratched pan‚ as well as offer tips on prevention and maintenance to help you get the most out of your cookware. Whether you’re a seasoned chef or a culinary novice‚ this article aims to provide you with the knowledge and expertise to keep your non-stick pans in top condition.

Understanding Non-Stick Coatings

Non-stick coatings‚ typically made from synthetic polymers‚ provide a friction-reducing layer on cookware surfaces‚ ensuring effortless food release and easy cleaning‚ while also preventing corrosion and wear.

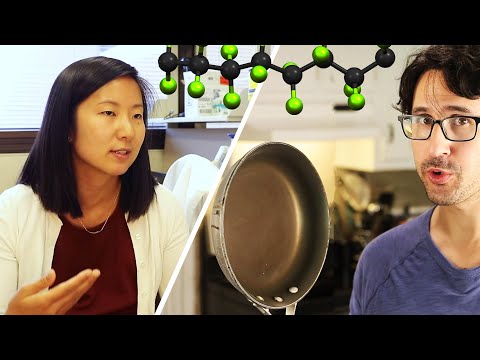

What is Teflon?

Teflon‚ a synthetic polymer coating‚ is the most widely recognized non-stick coating used in cookware. Chemically known as polytetrafluoroethylene (PTFE)‚ Teflon is a fluoropolymer that provides an exceptionally slippery surface‚ preventing food from adhering to it. This results in effortless food release‚ reduced risk of scratching‚ and easy cleaning. Teflon’s unique properties make it an ideal choice for non-stick cookware‚ as it can withstand high temperatures and is resistant to chemical corrosion. However‚ it is essential to note that Teflon is not a single‚ unified product‚ but rather a brand name that encompasses a range of non-stick coatings. The quality and performance of Teflon-coated cookware can vary significantly depending on the manufacturer and the specific type of coating used. Understanding the properties and limitations of Teflon is crucial for maintaining and utilizing non-stick cookware effectively.

Causes of Scratches and Peeling

Scratches and peeling on non-stick pans can be attributed to various factors. One primary cause is the use of abrasive cleaners‚ scouring pads‚ or metal utensils‚ which can damage the delicate non-stick coating. High heat‚ exceeding the recommended temperature limit‚ can also cause the coating to degrade and peel off. Additionally‚ cooking methods such as searing or frying at extremely high temperatures can lead to thermal shock‚ causing the non-stick coating to crack and flake off. Furthermore‚ storing non-stick pans in a way that causes them to rub against other cookware or utensils can result in scratches and damage. Lastly‚ using non-stick pans beyond their expected lifespan or neglecting regular maintenance can also contribute to the deterioration of the non-stick coating‚ ultimately leading to scratches and peeling. By understanding these causes‚ individuals can take preventive measures to maintain their non-stick cookware.

Consequences of a Damaged Non-Stick Coating

A damaged non-stick coating can have severe consequences‚ impacting both cooking performance and health. It is essential to address these issues promptly to prevent further deterioration and potential harm.

Health Risks

A damaged non-stick coating can pose significant health risks‚ particularly when the underlying metal is exposed. If ingested‚ toxic chemicals such as PFOA and PFOS can contaminate food‚ leading to potential health complications. Moreover‚ flaking Teflon particles can be inhaled‚ exacerbating respiratory issues like asthma.

Prolonged exposure to these toxins has been linked to various health problems‚ including cancer‚ reproductive disorders‚ and thyroid disease. It is crucial to address any damage to the non-stick coating promptly to prevent the leaching of hazardous substances into food. In severe cases‚ it may be necessary to discard the affected cookware to ensure a safe cooking environment. By taking proactive measures‚ individuals can minimize the risks associated with a damaged non-stick coating and maintain a healthy cooking routine.

In order to mitigate these health risks‚ it is essential to inspect your cookware regularly and take corrective action at the first sign of damage.

Impact on Cooking Performance

A damaged non-stick coating can significantly compromise cooking performance‚ leading to a range of issues that can be frustrating for home cooks and professional chefs alike. The most immediate effect is the loss of non-stick properties‚ causing food to stick to the surface and making cooking and cleaning more challenging.

Furthermore‚ scratches and peeling can create uneven heat distribution‚ resulting in hotspots that can burn or undercook food. This can lead to inconsistent results‚ affecting the texture‚ flavor‚ and overall quality of the finished dish. In addition‚ the exposed metal can react with acidic ingredients‚ imparting unwanted flavors and colors to the food. By restoring the non-stick coating or replacing the affected cookware‚ individuals can ensure optimal cooking performance and achieve the desired culinary outcomes.

Ultimately‚ a damaged non-stick coating can undermine the efficiency and enjoyment of cooking‚ making it essential to address any damage promptly.

Restoring and Fixing a Scratched Pan

Scratched non-stick pans can be revitalized through various methods‚ including coating removal‚ scratch repair‚ and surface restoration‚ providing a cost-effective alternative to replacing damaged cookware entirely.

Removing Old Non-Stick Coating

The first step in restoring a scratched non-stick pan is to remove the old coating. This process requires caution‚ as the coating can release toxic fumes when heated. To safely remove the coating‚ mix equal parts water and white vinegar in the pan‚ and bring to a boil. Reduce heat and let simmer for 10-15 minutes‚ allowing the coating to loosen. Then‚ use a soft sponge or cloth to gently scrape away the coating‚ taking care not to scratch the underlying metal. Rinse the pan thoroughly with soap and water‚ and dry with a towel. This process may need to be repeated several times to fully remove the old coating. It is essential to wear protective gloves and work in a well-ventilated area when removing the coating to minimize exposure to potential toxins.

Fixing Scratches

Once the old non-stick coating has been removed‚ any scratches on the metal surface must be addressed. To fix scratches‚ use a gentle metal polish or a mixture of equal parts water and baking soda to create a paste. Apply the polish or paste to the scratched area and rub gently with a soft cloth in a circular motion. Rinse the pan thoroughly with soap and water‚ and dry with a towel. For deeper scratches‚ a stainless steel scratch remover may be necessary. Be sure to follow the manufacturer’s instructions when using any cleaning products. It is crucial to smooth out the metal surface to ensure a successful re-coating process. By fixing scratches‚ you can prevent the growth of bacteria and other microorganisms‚ ensuring a safe and healthy cooking environment. Regular maintenance can also help prevent scratches from forming in the future.

Restoring Non-Stick Surface

After fixing scratches and removing old non-stick coating‚ the next step is to restore the non-stick surface. This can be achieved by applying a new layer of non-stick coating or seasoning the pan. For Teflon-based coatings‚ use a reputable re-coating product specifically designed for cookware‚ following the manufacturer’s instructions. Alternatively‚ for a PFOA-free option‚ consider seasoning the pan with a natural oil‚ such as flaxseed or coconut oil. Apply a thin‚ even layer of oil to the pan’s surface and bake in the oven at 350°F (175°C) for an hour. Allow the pan to cool before wiping off any excess oil. Repeat the process several times to build up a robust non-stick layer. By restoring the non-stick surface‚ you can revive your pan’s original performance and enjoy effortless food release and cleaning once again. Proper maintenance will help extend the life of the new non-stick surface.

Prevention is Better than Cure

Proactive care and maintenance can significantly extend the lifespan of your non-stick pan‚ preventing scratches and peeling from occurring in the first place. Simple habits can make a substantial difference.

Maintenance Tips

To maintain your non-stick pan’s optimal condition‚ it is essential to adopt a few simple habits. Always clean the pan gently with mild soap and water‚ avoiding abrasive materials that can scratch the surface. Dry the pan thoroughly after washing to prevent water spots from forming. When storing‚ place a paper towel or soft cloth between stacked pans to prevent scratching.

Avoid using metal utensils‚ as they can easily damage the non-stick coating. Instead‚ opt for silicone‚ wooden or plastic utensils. For tougher cleaning tasks‚ mix equal parts water and white vinegar in the pan‚ bringing the solution to a boil before reducing heat and letting it simmer for a few minutes. This method effectively removes stubborn residue without compromising the non-stick surface. By following these straightforward maintenance tips‚ you can enjoy your non-stick pan for years to come.

I particularly appreciated the section on prevention and maintenance; these tips will undoubtedly extend the lifespan of my own non-stick pans! Overall, an informative read that has left me feeling more confident about caring for my cookware.

As someone new to cooking, I found this article incredibly helpful! The author broke down complex concepts into easily digestible pieces, allowing me to grasp even the most technical aspects of non-stick coatings.

One thing I would have liked to see was more visuals – diagrams or images illustrating common issues with non-stick pans would have greatly enhanced my understanding of these problems.

I thoroughly enjoyed reading this informative article about restoring non-stick pans! As someone who cooks frequently, I

While I appreciated the comprehensive overview of non-stick coatings, I felt that some sections could have been condensed or reorganized for better flow. Nonetheless, the author